NHMF best practice

These two new best practice sections will help social landlords to maintain quality homes in an increasingly challenging economic environment. The Compliance Section has a set of topical guides summarising social landlords’ responsibilities for meeting essential statutory health and safety requirements and explain how to do this economically and efficiently. The Fuel Saving Section explains how to include a fuel saving strategy as a key aspect of an organisation’s business plan. The Guide then sets out how to develop a practical improvement strategy as an integral part of the asset management programme and how to successfully deliver the improvements and manage the risks. There are also best practice training courses which relate to this guide.

Chapter 6: Managing risk and ensuring quality

Introduction

Improving the energy efficiency of existing housing is a risky business. It involves the integration of new materials, products and systems using installation processes that are new to managed housing. To achieve significant reductions in fuel use, fuel cost and carbon dioxide emissions a range of improvement measures have to be installed in each house, either all at once or in coordinated stages according to a medium-term plan. The measures include:

improvements to the building fabric (insulation and air-tightness), the building services (ventilation, space heating, water heating and lighting) and the addition of renewable energy technologies (usually solar thermal and solar photovoltaic systems). All of these measures interact – for example insulation and air tightness measures reduce air infiltration and air leakage, creating a critical requirement for better deliberate ventilation; and they reduce heat losses, resulting in a need for smaller heating appliances with more responsive controls as well as increasing the risk of overheating in warm weather. The fact that the measures are usually installed while the dwelling is occupied introduces more interactions, and more risk.

Therefore this chapter addresses three questions:

- Why do energy efficiency improvement projects rarely deliver the predicted reductions in fuel bills and emissions, and what contributes to the so-called "performance gap"?

- What are the risks of building-in defects, and how can we mitigate those risks?

- What are the key points to watch out for, at each stage of the process?

Research from the eighty-six projects in the Retrofit for the Future programme run by the Technology Strategy Board (now Innovate UK), and other, subsequent projects, have helped us to understand the interactions between measures, the risks that arise from them, and how to manage them.

Good practice guidance has become available, and risk management tools have been developed to help housing organisations to identify and mitigate risks, and to ensure that their fuel-saving programmes deliver quality work. It is important that housing organisations understand and manage risks, because the consequences of not doing so are serious, including:

- poor energy performance (i.e. fuel cost savings significantly less than predicted, leaving residents with high fuel bills)

- condensation, mould growth and the deterioration of finishes, fabric and structure

- overheating in warm weather

- diminished resident satisfaction (and increased complaints)

- erosion of asset value and resources

- loss of reputation and undermining the commitment to fuel-saving

In order to manage risks it is first necessary to understand the fuel-saving improvement process, then to introduce risk mitigation techniques based on documented good practice standards and procedures.

The retrofit process

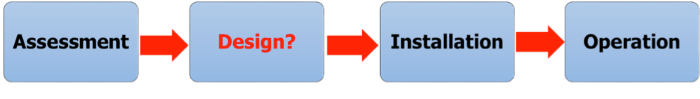

Figure 6.1 shows the process followed in many publicly funded fuel-saving programmes such as the Energy Company Obligation (ECO) and the now-defunct Green Deal Home Improvement Fund. It is simple: the dwelling is assessed and appropriate improvement measures are identified; a design is prepared; improvement measures are installed; and the improved dwelling is occupied with the new systems, etc., in place and in operation. Theoretically, installation quality is governed by a Publicly Available Specification (PAS 2030), which sets standards for the training of installers and the processes they use.

Figure 6.1 A simple representation of the retrofit process

Unfortunately almost every project that has followed this process has failed to deliver the improvements in energy performance predicted at the assessment stage – in many cases by significant margins. Some projects have also suffered from technical defects such as condensation. To understand why this has happened it is necessary to examine where the process goes wrong.

Where do fuel-saving improvements go wrong?

One problem is that the design stage of the process is rarely present (which is why it is shown in red with a "?" in the "Design" box in Figure 6.1). Although PAS 2030 requires the installers of measures to work to documented designs, most processes implemented in large-scale, funded programmes (e.g. ECO) do not include a design or specification stage; instead they move straight from an assessment that identifies potentially appropriate improvement measures to installation of those measures, with very little either generic or site-specific consideration of how those measures interact or how they should be installed.

The reason why the omission of the design stage of the process is critical is that the three places where improvements often fail are all places where design input, attention to detail with drawings, is critical. They are:

- at the corners, junctions and edges where building elements meet, and around openings, where continuity of insulation and of the air barrier are critical to minimising thermal bridging and to eliminating air infiltration and air leakage

- at the interfaces between the building fabric and the building services, where heating and ventilation systems and their controls must be matched to heat loss and air permeability

- at the interfaces between systems and people, where commissioning, handover, control, and maintenance are critical to achieving the intended performance

This is also the reason why PAS 2030 is not fit for purpose, and should not be relied on by housing organisation as an assurance of quality. PAS 2030 specifies that installers should be certified according to measure-specific training schemes established by industry before the importance of whole-house improvement was recognised. Its focus is on improving individual elements of the dwelling by installing individual measures, but not on the junctions between them; and on installing systems correctly, but not on the interfaces between those systems and the building fabric or the people who will use and maintain them. PAS 2030 includes a separate annex specifying training and certification requirements for the installation of each individual measure or system, but has almost nothing to say about the corners, junctions, edges and interfaces that are the places where problems occur. Thus it preserves the fragmentation of the industry rather than promoting a robust, integrated approach.

An improved process

In practice, many housing organisations developed their own procedures for assuring the quality of improvement work, during the Decent Homes and other programmes and subsequently when installing measures funded by the CERT, CESP and ECO programmes.

These procedures include assessing dwellings, consulting residents, designing and specifying improvements, engaging contractors via framework contracts and inspecting work to check compliance with designs and specifications. Housing organisations should build on this valuable experience when venturing into energy efficiency improvements.

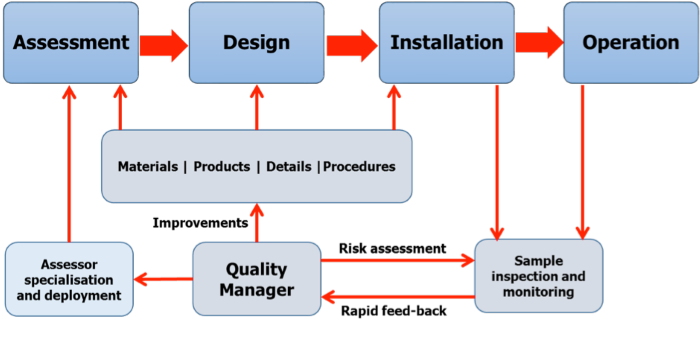

A robust process for medium- and large-scale fuel-saving programmes is shown in Figure 6.2.

Figure 6.2 - A robust process for medium- and large-scale fuel-saving programmes

Figure 6.2 - A robust process for medium- and large-scale fuel-saving programmes, incorporating risk management and quality assurance.

Figure 6.2 has two key features. First, there is a library of materials, products construction details and documented procedures (for assessment, design, installation and quality assurance) that are used throughout the process.

These are based on experience and good practice guidance, and because delivering improvements is a learning process they are subject to change, under the control of the Quality Manager. There is considerable scope for housing organisations to share their fuel-saving improvement libraries with each other, possibly via the NHMF, or to develop them collaboratively through common procurement processes. There is also scope for framework contractors to contribute to them. However, it should be noted that many designs and procedures may be stock-specific.

The second key feature is the Quality Manager, who might be a senior programme manager, an experienced project manager, an in-house technical surveyor or architect, or a small team of such people. Irrespective of background it is also preferable that the lead Quality Manager is a Retrofit Coordinator, i.e. an individual trained by the Centre of Refurbishment Excellence (CoRE) and who holds the CoRE Diploma in Retrofit (Retrofit Coordinator) or has completed the CoRE | NHMF Retrofit Asset Manager training.

The Quality Manager or Quality Management Team should have five responsibilities:

- Ensuring that dwellings are properly assessed prior to measures being designed, specified and installed. The assessment process should be more than a simple SAP energy rating assessment carried out by a Domestic Energy Assessor: it should embrace all relevant aspects of the dwelling, including its current performance, its construction type and state of repair, planning constraints, design constraints, cost considerations and a technical risk assessment. Specialist assessors should be deployed to ‘vulnerable’ dwellings (i.e. those built before 1920, which may have vapour permeable construction) and to dwellings where the installation of high-risk measures (e.g. solid wall insulation, communal heating or whole house mechanical ventilation with heat recovery) is anticipated.

- Maintaining the library of materials, products, construction details and procedures. inevitably, the library will continually change as the scope of the improvement programme develops, and in the light of experience. There should be rapid feed-back from inspections and from monitoring and evaluation work to ensure that elements that prove problematic are quickly improved or replaced, before further defective installations are completed. Updates should be subject to a strict change management procedure and communicated clearly to users (i.e. assessors, designers, specifiers and installers).

- Operating an inspection process, involving inspections of work both during and after the installation of measures. Inspections are expensive, and there is unlikely to be sufficient resource to inspect the installation of every measure in every dwelling. Technical risk assessments should therefore be used to target inspection resources on the highest risks, i.e. where problems are most likely to occur, with the greatest impact. Elsewhere, good quality improvement work will rely on well-trained site supervisors.Operating a sample monitoring regime, involving both basic energy performance monitoring and simple post occupancy evaluation (i.e. proforma interviews with residents) to ensure that the fuel saving programme delivers what residents are promised. More elaborate and expensive energy performance monitoring, post construction reviews and detailed post occupancy evaluation may be appropriate in some cases, especially where complex or high-risk whole-dwelling fuel saving imrpovement has been carried out. The monitoring regime is critical to the continuous improvement of the overall retrofit process.

- Finally, collaborating with housing managers to investigate residents’ complaints, rectify problems and feed experience back to the library.

How to ensure successful improvement

Key actions for managing risk and ensuring successful improvement, listed in the order of the stages described above, include:

- Build risk management and quality assurance processes into the overall programme. Employ specialists, including architects with fuel saving improvement experience and at least one Retrofit Coordinator trained by CoRE.

- Don’t under-resource assessment: match assessors’ skills to buildings and anticipated measures. Recognise that vulnerable buildings may require specialist attention.

- Identify appropriate improvement measures to suit the residents, the buildings and the local contexts. Spend time understanding residents’ constraints. Beware of over-optimistic performance predictions (especially if work will be funded by fuel cost savings and residents are currently under-heating their homes).

- When evaluating improvement options, adopt a "fabric-first" approach: first improve the insulation and air tightness of the building envelope, in order to reduce heat loss; then improve the building services, to increase efficiency; finally, add appropriate renewable energy systems to "top-up" performance to the required standard.

- Establish an air-tightness and ventilation strategy to ensure good internal air quality, control moisture and reduce the risk of condensation and mould growth. Recognise that in most dwellings deliberate ventilation will need to be improved if insulation is added or the dwelling is made more air-tight.

- Specify the materials and products to be used. Design the construction details at all junctions, corners and edges of building elements. Maintain the integrity of the insulated envelope and the continuity of the air-barrier.

- Match the type and capacity of heating and ventilation systems to the reduced heat loss and air permeability respectively. Keep controls as simple as possible, and readily accessible.

- Ensure that ventilation systems include provision for fresh air inlet as well as for stale air extraction. Recognise that mechanical ventilation with heat recovery (MVHR) will not work effectively if the air permeability of the building envelope is more than 3 m3/m2hr @ 50 Pa. MVHR is also very difficult to install properly in existing buildings. Ensure access is provided for filter cleaning or replacement.

- Incorporate measures to reduce overheating, including external shading, reduction of internal gains (by installing very energy efficient lamps and appliances) and provision for secure night-time ventilation in summer. Ensure that any ventilation system with heat recovery includes summer by-pass of the heat exchanger.

- Avoid using separate installers for each improvement measure: use multi-skilled installation teams or require installers to cooperate. Ensure that installers are properly briefed by means of "toolbox talks" – especially about air tightness.

- Procure the design, not a contractor’s or installer’s interpretation of it. Implement change management control to eliminate inappropriate substitutions of materials or products. Do not allow installer design unless it is pre-documented and approved by the designer.

- Undertake pre-completion testing (pressure testing and thermography); target sample testing and inspections using risk assessments. Provide rapid feedback to facilitate remedial work, and improvements in designs and specifications.

- Commission all building systems together at the same time, not separately, in accordance with a pre-agreed process, and obtain commissioning certificates.

- Adopt a robust handover process: explain what has been installed and how to use it by means of verbal briefings, supplemented by graphic instructions and follow-up visits by trained resident advisors.

- Provide residents with advice about the use of controls. Explain how risks of condensation and of overheating can be managed. Explain the consequences of disabling ventilation systems. Promote behaviour that will reduce fuel costs.

- Brief the maintenance team, providing comprehensive descriptions of the systems, components, controls and service requirements: they are as important as the residents!

- Undertake post-construction reviews, post occupancy evaluation and monitoring to confirm performance, internal air quality and user acceptability. Target monitoring using risk assessments and focus on the highest risks. Provide rapid feedback to the quality assurance team so that materials, products, details and processes can be improved.

Case Study: Risk Management in the London RE:NEW Programme

The Greater London Authority (GLA) RE:NEW programme provides a wide range of support services for local authorities’, housing associations’ and private landlords’ fuel saving projects in London. The programme aims to: promote and support retrofit at scale; overcome barriers to retrofit; reduce carbon dioxide emissions associated with energy use; and reduce London residents’ fuel costs and fuel poverty. RE:NEW is funded by the GLA and the European Investment Bank, and administered for the GLA by CAPITA.

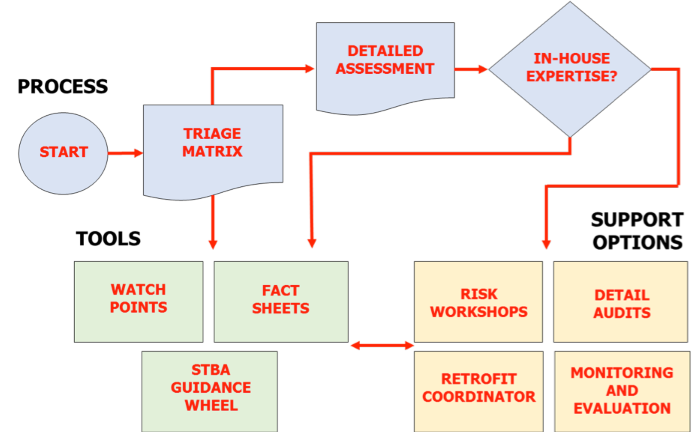

Many housing organisations see technical risks as a barrier to fuel saving improvements. Helping housing organisations to manage technical risk removes that barrier as well as improving the quality of the work carried out. Therefore consultants working for CAPITA’s RE:NEW support team have developed a suite of risk management techniques and tools to define and mitigate the inherent technical risk associated with most individual retrofit measures and, crucially, with combinations of measures. These tools include a risk management process, a triage matrix, a detailed assessment procedure, a set of risk management tools, and a range of risk management support options. The risk management process, tools and support options are illustrated in Figure 6.3.

Figure 6.3 - The GLA RE:NEW retrofit risk management process, tools and support options

(Diagram courtesy of the CAPITA RE:NEW support team)

© RE:NEW | Six Cylinder Ltd | ArchiMetrics Ltd | Rickaby Thompson Associates Ltd

Projects that are proposed for support from RE:NEW are first assessed with the triage matrix. The matrix is used to calculate a risk score that is determined by the inherent risk associated with the individual fuel saving measures proposed and the risk associated with each combination of measures. Risks are scored on a scale of 0 (no risk) to 3 (high risk). For example, a project combining communal heating (inherent risk 3) with external wall insulation (inherent risk 2) attracts a score of 3 for the combination of measures (because EWI can exacerbate overheating caused by communal heating) so the total score is 8, which is then divided by 2 (the number of measures) to give an overall risk score of 4, which is high.

If a project is assessed as low risk, the risk management tools are made available to the project team. These consist of Watch Points, detailed technical Fact Sheets, and the Guidance Wheel published by the Sustainable Traditional Buildings Alliance (STBA – see www.responsible-retrofit.org/wheel/), which is itself a source of extensive technical references. Lists of watch points are available for each stage of the retrofit process (assessment, design, installation and commissioning, handover and operation) and for the following topics:

- Floor insulation

- Cavity wall insulation

- Solid wall insulation

- Loft and roof insulation

- Windows and external doors

- Draught-proofing and air-tightness

- Ventilation

- Heating

- Heat pumps

- Water heating

- Solar water heating

The Fact Sheets cover the following topics:

- Interstitial condensation

- Surface condensation and mould

- Air leakage and ventilation

- Thermal bridging

- Water ingress

- Overheating

If a project is assessed by using the triage matrix as high risk, a further assessment is made, using a detailed questionnaire, to establish whether the project team (i.e. the designers and specifiers, and the contractors and installers) has appropriate experience and expertise, and whether appropriate risk mitigation is included in the project plan. If this is the case then the overall risk score is reduced, and the project team is again referred to the risk management tools.

If the project team is assessed as not having appropriate experience, or not applying appropriate risk mitigation, then the project team is offered one or more of the support options. These consist of:

- Risk workshops involving the whole project team and covering general retrofit risk management and/or the risks associated with specific fuel saving measures

- Support from a qualified Retrofit Coordinator, potentially including design and specification assistance, ventilation assessments and strategies, moisture management strategies, auditing of details for thermal bridging and air tightness, and support for the installation, commissioning and handover processes

- Monitoring and evaluation, including sample quality assurance inspections and testing, and rapid feedback to improve the overall project process as it proceeds

The approach adopted by the RE:NEW support team and its consultants is that risk management in large scale retrofit projects requires a systematic approach spanning from strategy to detail, and a range of consistent and transparent assessment and support tools. Every project is different, requiring different packages of fuel saving measures, and some measures are inherently riskier than others (both individually and in combination). The skills and experience of retrofit teams also vary. Risk management activity should therefore be tailored to suit projects, even though there will be recurring themes such as moisture management, ventilation, air tightness and thermal bridging. Demonstrating robust risk mitigation is important to protect occupants, to protect the buildings, to protect investment and to provide everyone with confidence in fuel saving programmes.

The risk-management tools developed for the London RE:NEW programme are to be made available nationally by the RE:NEW support team and the consultants who developed them.